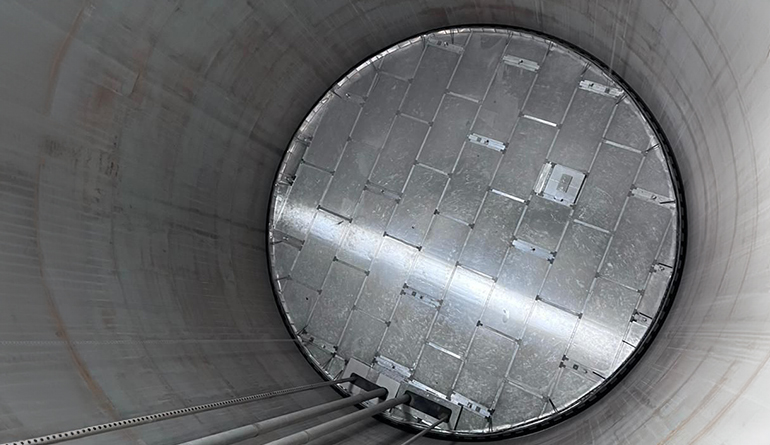

Internal Floating Roofs (IFRs) are designed to float on the surface of the stored liquid inside storage tanks, significantly reducing vapor emissions and product loss. These roofs are commonly used in industries such as petroleum, chemicals, and aviation fuel storage to enhance safety and efficiency.

Benefits of Internal Floating Roofs

Vapor Emission Reduction

Internal floating roofs are highly effective in reducing vapor emissions, helping companies comply with stringent environmental regulations and contributing to sustainability.

Product Loss Prevention

By minimizing the surface area exposed to the atmosphere, IFRs reduce evaporation losses, ensuring that more of the stored product remains intact.

Enhanced Safety

IFRs provide an additional layer of safety by reducing the risk of fires and explosions, as they minimize the build-up of flammable vapors.

Cost Efficiency

With reduced product loss and lower maintenance requirements, internal floating roofs offer significant cost savings over the long term.

Applications & Industries

Petroleum and Gas

Internal floating roofs are extensively used in petroleum storage tanks to reduce vapor emissions and prevent product loss, enhancing the overall safety and efficiency of storage operations.

Chemical Storage

Ideal for the chemical industry, IFRs help in reducing contamination risks and ensuring the integrity of stored chemicals by minimizing vapor exposure.

Aviation Fuel Storage

In aviation fuel storage, IFRs are critical for maintaining fuel quality and reducing evaporation losses, ensuring that the stored fuel remains usable for longer periods.

Water and Wastewater Treatment

IFRs are also used in water and wastewater treatment plants to control odors and prevent evaporation, maintaining the quality of stored water.

Technical Specifications

Internal floating roofs are typically constructed from materials such as aluminum and stainless steel, providing excellent corrosion resistance and durability. They feature a lightweight design that allows them to float on the surface of the stored liquid, with seals that prevent vapor escape and ensure efficient operation.

Installation & Maintenance

Installation Process

Ateco's internal floating roofs are designed for easy installation, with comprehensive guides and support to ensure a seamless setup process.

Maintenance Guidelines

Regular maintenance is essential to keep IFRs functioning effectively. Our guidelines include periodic inspections, seal checks, and routine cleaning to maintain optimal performance.

Sustainability and Environmental Impact

Internal floating roofs play a crucial role in sustainable development by reducing harmful vapor emissions and preventing product loss. Their use contributes to environmental protection and helps companies meet sustainability goals.

FAQs

What is an internal floating roof and how does it work?

An internal floating roof is a floating cover inside a storage tank that rests on the surface of the stored liquid, reducing vapor emissions and evaporation losses.

What materials are used in internal floating roofs?

IFRs are commonly made from lightweight, corrosion-resistant materials such as aluminum and stainless steel, ensuring durability and long-term performance.

How often should internal floating roofs be inspected and maintained?

Regular inspections, typically annually, are recommended to ensure seals and components are functioning correctly and to perform any necessary maintenance.

What are the key benefits of installing an internal floating roof?

Key benefits include reduced vapor emissions, minimized product loss, enhanced safety, and cost efficiency.

Why Choose Ateco’s Internal Floating Roofs?

Ateco’s internal floating roofs are engineered to the highest standards, offering superior performance, durability, and safety. Our innovative designs and commitment to quality ensure that our IFRs meet the specific needs of various industries, providing reliable and efficient storage solutions.